The Power Of Precision: Exploring The Role Of Makeup Kit CAD Blocks In Design And Manufacturing

The Power of Precision: Exploring the Role of Makeup Kit CAD Blocks in Design and Manufacturing

Related Articles: The Power of Precision: Exploring the Role of Makeup Kit CAD Blocks in Design and Manufacturing

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Power of Precision: Exploring the Role of Makeup Kit CAD Blocks in Design and Manufacturing. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Power of Precision: Exploring the Role of Makeup Kit CAD Blocks in Design and Manufacturing

In the world of cosmetics, aesthetics and functionality intertwine seamlessly. From the intricate design of a lipstick tube to the ergonomic shape of a compact mirror, every detail contributes to the overall user experience. This pursuit of perfection is further amplified in the manufacturing process, where precision and efficiency are paramount. To achieve this ideal, designers and manufacturers rely on a powerful tool: CAD blocks.

This article delves into the world of makeup kit CAD blocks, exploring their significance in the design and manufacturing process, and highlighting the benefits they offer.

Understanding the Essence of CAD Blocks

CAD, short for Computer-Aided Design, is a technology that utilizes computer software to create and modify designs. CAD blocks, within this context, are pre-designed, reusable components that represent specific objects or elements. These blocks act as digital building blocks, streamlining the design process by eliminating the need to repeatedly create the same elements from scratch.

The Makeup Kit CAD Block: A Digital Blueprint for Beauty

Makeup kits, by their very nature, are intricate assemblies of various components. From the external packaging to the internal compartments housing individual products, each element plays a crucial role in the overall functionality and aesthetic appeal. This complexity demands a meticulous design process, where every detail is carefully considered.

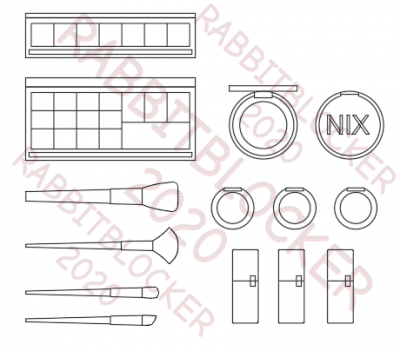

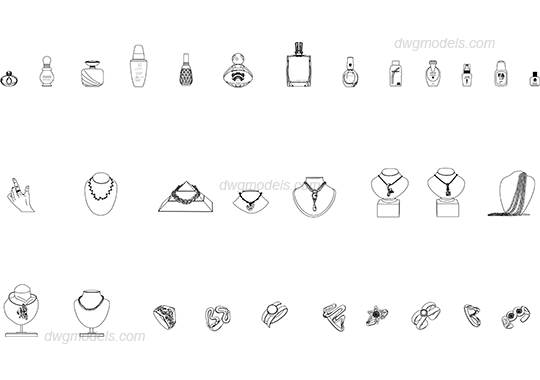

Here, makeup kit CAD blocks emerge as invaluable assets. They represent the individual components of a makeup kit – the containers, compartments, mirrors, applicators, and other elements – as digital representations. These blocks are meticulously detailed, capturing the precise dimensions, shapes, and materials of each component.

Benefits of Utilizing Makeup Kit CAD Blocks:

- Enhanced Efficiency: By eliminating the need to repeatedly design individual components, makeup kit CAD blocks significantly accelerate the design process. This allows designers to focus on the overall kit design and explore various iterations with greater speed and efficiency.

- Precision and Accuracy: CAD blocks provide a foundation of precision, ensuring that all components are designed to exact specifications. This minimizes errors and inconsistencies, leading to a more refined and functional final product.

- Seamless Integration: CAD blocks can be seamlessly integrated into various design software platforms, facilitating collaboration between different teams and stakeholders. This allows for a unified design approach, minimizing the potential for discrepancies.

- Cost Savings: The efficiency and precision offered by CAD blocks translate into cost savings. By reducing design time and minimizing errors, manufacturers can optimize their production processes, leading to greater cost-effectiveness.

- Improved Communication: CAD blocks serve as a universal language for designers, engineers, and manufacturers. They provide a clear and concise representation of the design intent, minimizing the potential for miscommunication and ensuring that all parties are working from the same blueprint.

Types of Makeup Kit CAD Blocks

Makeup kit CAD blocks are available in a variety of formats, catering to the specific needs of different design projects. Some common types include:

- Basic Blocks: These blocks represent fundamental shapes and elements, such as boxes, cylinders, and spheres. They are used to create the overall structure of the makeup kit.

- Component Blocks: These blocks represent specific components of the makeup kit, such as containers, compartments, mirrors, and applicators. They are often detailed with dimensions, materials, and other relevant specifications.

- Assembly Blocks: These blocks represent the complete makeup kit, incorporating all the individual components in their correct positions and relationships. They are used for visualizing the final product and evaluating its overall design.

The Power of Customization:

While pre-designed CAD blocks offer a significant advantage, they can be further customized to meet specific design requirements. Designers can modify the dimensions, materials, and other attributes of existing blocks to create unique and innovative makeup kit designs.

Beyond Design: The Role of CAD Blocks in Manufacturing

CAD blocks are not merely design tools; they play a crucial role in the manufacturing process as well. They are used to create detailed drawings and models that guide the production of the makeup kit.

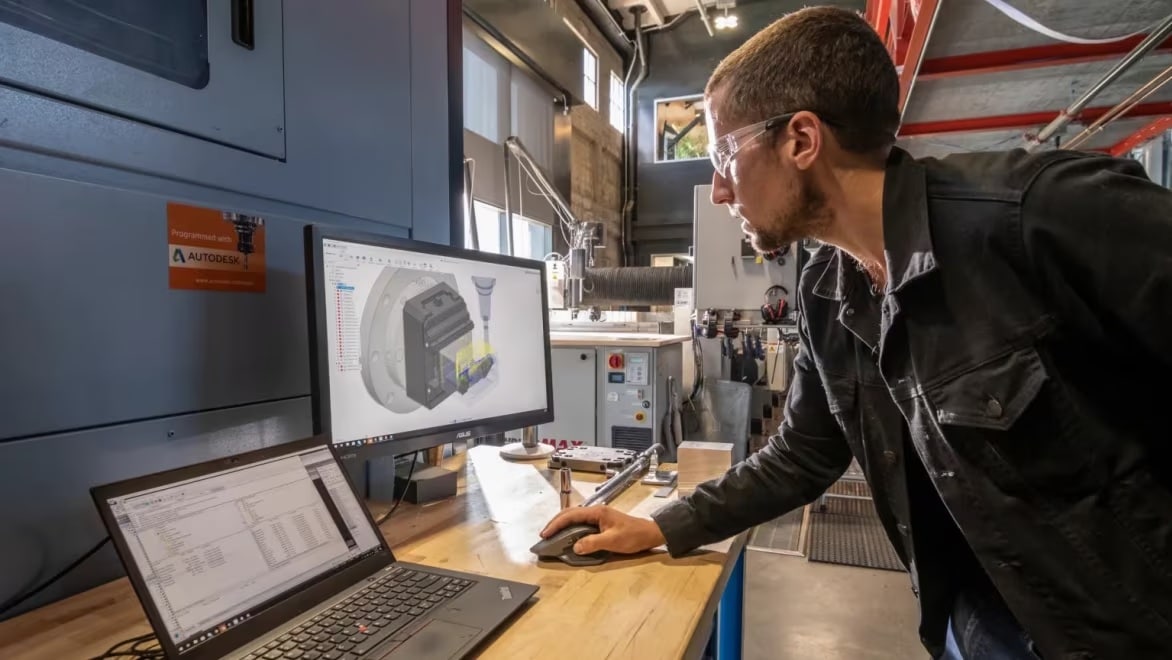

- CNC Machining: CAD blocks can be used to generate CNC (Computer Numerical Control) programs, which instruct automated machines to precisely cut and shape the components of the makeup kit.

- 3D Printing: CAD blocks can be utilized to create 3D printed prototypes, allowing manufacturers to test and evaluate the design before committing to full-scale production.

- Mold Creation: CAD blocks are essential for creating molds used in injection molding, a common manufacturing process for creating plastic components.

FAQs on Makeup Kit CAD Blocks

1. What software platforms are compatible with makeup kit CAD blocks?

Many popular CAD software platforms, such as SolidWorks, AutoCAD, and Creo, support the use of CAD blocks.

2. Where can I find makeup kit CAD blocks?

There are several online marketplaces and libraries that offer a wide range of makeup kit CAD blocks, both free and paid.

3. Can I create my own makeup kit CAD blocks?

Yes, you can create your own CAD blocks using specialized software. This allows for greater customization and control over the design process.

4. Are makeup kit CAD blocks essential for all design projects?

While not mandatory, makeup kit CAD blocks offer significant benefits, particularly for complex designs and large-scale production runs.

5. What are the limitations of makeup kit CAD blocks?

CAD blocks are digital representations, and they cannot fully capture the nuances of real-world materials and processes. It is essential to consider these limitations when using CAD blocks.

Tips for Utilizing Makeup Kit CAD Blocks Effectively

- Choose the Right Software: Select a CAD software platform that meets your specific design needs and offers compatibility with makeup kit CAD blocks.

- Utilize a Library: Explore online libraries and marketplaces to access a wide range of pre-designed blocks.

- Customize When Necessary: Modify existing blocks to create unique and innovative designs.

- Consider Material Properties: Ensure that the CAD blocks accurately represent the material properties of the components.

- Validate the Design: Create prototypes and test the design before committing to full-scale production.

Conclusion

Makeup kit CAD blocks are a powerful tool for designers and manufacturers in the cosmetics industry. They streamline the design process, enhance precision, and facilitate efficient manufacturing. By embracing this technology, brands can create high-quality, innovative makeup kits that meet the demands of a discerning consumer base.

Closure

Thus, we hope this article has provided valuable insights into The Power of Precision: Exploring the Role of Makeup Kit CAD Blocks in Design and Manufacturing. We hope you find this article informative and beneficial. See you in our next article!